High-Quality Pressure Transmitter With Diaphragm Seal: A Comprehensive Guide

By:Admin

{Name of the company} is a leading manufacturer of industrial automation and control solutions. With a focus on innovation and quality, the company has established a strong reputation for providing reliable and high-performance products to a wide range of industries, including oil and gas, petrochemical, pharmaceutical, and more. {Name of the company} is committed to meeting the unique needs of its customers with cutting-edge technologies and exceptional customer service.

[Pressure Transmitter With Diaphragm Seal]

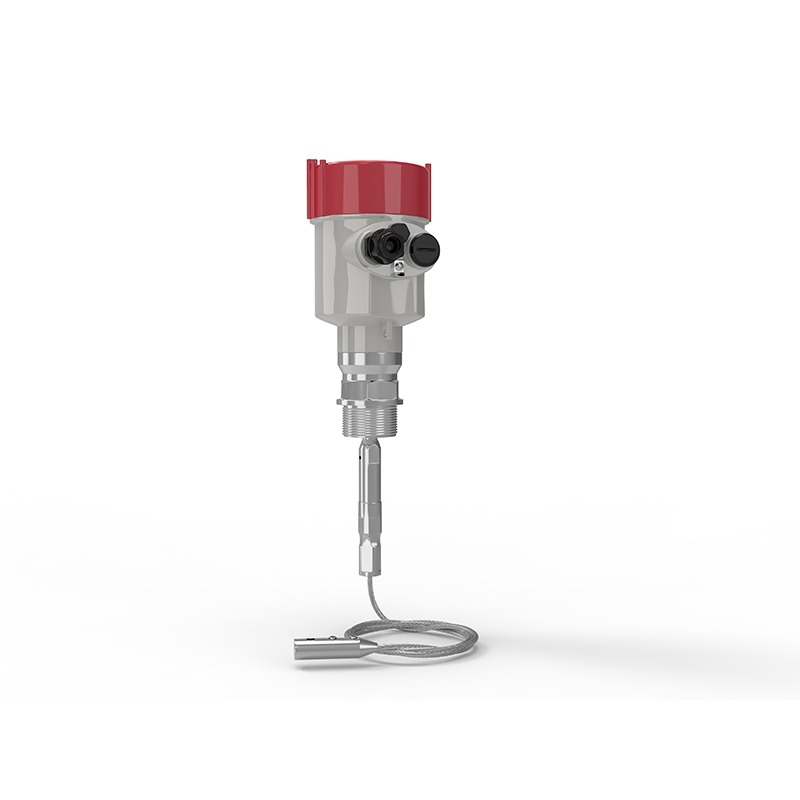

{Name of the company} is proud to announce the release of its latest product, the Pressure Transmitter with Diaphragm Seal. This new transmitter is designed to accurately measure and transmit pressure readings in challenging industrial environments, where the process medium is corrosive, viscous, or contains solid particles. The diaphragm seal protects the sensitive components of the transmitter, ensuring reliable and accurate measurements even in the harshest conditions.

The Pressure Transmitter with Diaphragm Seal is available in a wide range of pressure ratings, from low to high, and is suitable for use with a variety of process media, including liquids, gases, and steam. The transmitter is also available with a range of output options, including analog, digital, and wireless, to meet the diverse needs of different industrial applications.

One of the key features of the Pressure Transmitter with Diaphragm Seal is its robust construction, which ensures long-term performance and reliability. The transmitter is made from high-quality materials that are resistant to corrosion and wear, and it is designed to withstand extreme temperatures and pressures. As a result, {Name of the company}'s new transmitter is an ideal solution for industries that require precise and dependable pressure measurement, such as oil and gas production, chemical processing, and power generation.

In addition to its exceptional durability, the Pressure Transmitter with Diaphragm Seal is also easy to install and maintain. Its compact and lightweight design makes it suitable for installation in tight spaces, and its intuitive interface allows for quick and simple configuration. Furthermore, the transmitter is equipped with advanced diagnostics and self-calibration features, which help to reduce downtime and maintenance costs, and ensure continuous and accurate measurement.

{Name of the company}'s commitment to quality and innovation is evident in the development of the Pressure Transmitter with Diaphragm Seal. The company's team of skilled engineers and technicians have utilized their expertise and experience to design a transmitter that meets the highest industry standards for performance, accuracy, and reliability. Furthermore, {Name of the company} has subjected the transmitter to rigorous testing and validation procedures to ensure its compliance with international regulations and quality assurance guidelines.

{Quote from company spokesperson} "We are excited to introduce our new Pressure Transmitter with Diaphragm Seal to the market. This innovative product represents a significant advancement in pressure measurement technology, and we are confident that it will provide our customers with the performance and reliability they need to optimize their processes and operations. At {Name of the company}, we are dedicated to delivering solutions that exceed our customers' expectations, and the Pressure Transmitter with Diaphragm Seal is a clear demonstration of that commitment."

{Name of the company}'s new Pressure Transmitter with Diaphragm Seal is now available for purchase, and the company is offering comprehensive technical support and customer service to assist with installation, configuration, and ongoing maintenance. With this new addition to its product portfolio, {Name of the company} has further solidified its position as a trusted provider of advanced industrial automation and control solutions, and is poised to make a positive impact on a wide range of industrial applications.

Company News & Blog

Magnetic Flow Meters for Wastewater: A Solution for Accurate Flow Measurement

The demand for efficient and reliable wastewater management solutions has been on the rise in various industries. In response to this growing need, {Company} has introduced a new line of Magnetic Flow Meters specifically designed for wastewater applications. These cutting-edge flow meters are poised to revolutionize the way wastewater is measured and managed, offering unparalleled accuracy and performance.{Company} is a leading provider of innovative flow and liquid measurement solutions, with a strong focus on delivering high-quality products that meet the unique needs of its customers. With a proven track record in the industry, {Company} has consistently pushed the boundaries of technology and engineering to develop solutions that set new standards for efficiency and reliability.The newly launched Magnetic Flow Meters for wastewater are the latest addition to {Company}'s extensive portfolio of flow measurement products. These flow meters are built to withstand the harsh and challenging conditions often encountered in wastewater applications, making them the ideal choice for industries such as municipal wastewater treatment plants, industrial wastewater management, and agricultural wastewater monitoring.What sets {Company}'s Magnetic Flow Meters apart is their advanced design and innovative features. These flow meters utilize a non-intrusive measurement principle, which means they do not have any moving parts that come into contact with the wastewater. This not only ensures minimal maintenance and long-term reliability but also minimizes the risk of clogging and damage, resulting in uninterrupted and accurate measurements.In addition, the Magnetic Flow Meters are equipped with state-of-the-art electronic components and advanced signal processing capabilities, allowing for precise and real-time measurement of wastewater flow. This level of accuracy is crucial for ensuring optimal wastewater management, particularly in applications where precise flow measurement is essential for regulatory compliance and operational efficiency.{Company} has also integrated intelligent features into the Magnetic Flow Meters, such as diagnostics and self-check capabilities, to provide users with valuable insights into the performance and health of the flow meters. This proactive approach to maintenance and problem detection helps to minimize downtime and the potential for inaccuracies in measurement, further enhancing the overall reliability of the wastewater management system.Another key advantage of {Company}'s Magnetic Flow Meters is their versatility and adaptability. These flow meters are available in a range of sizes and configurations to accommodate different pipe diameters and flow rates, making them suitable for a wide variety of wastewater applications. Furthermore, they can be easily integrated with existing monitoring and control systems, thanks to their compatibility with various communication protocols and interfaces.The introduction of {Company}'s Magnetic Flow Meters for wastewater represents a significant leap forward in the field of wastewater management. By combining advanced technology, robust design, and user-centric features, {Company} has once again demonstrated its commitment to delivering solutions that address the evolving needs of the industry and contribute to a more sustainable and efficient use of resources.In conclusion, {Company}'s Magnetic Flow Meters for wastewater are set to make a lasting impact on how wastewater is measured and managed. With their cutting-edge technology, reliability, and adaptability, these flow meters offer a compelling solution for industries seeking to optimize their wastewater management processes. As the industry continues to evolve, {Company} remains at the forefront of innovation, driving positive change and empowering businesses to achieve their wastewater management goals with confidence.

All You Need to Know About High-Performance Absolute Pressure Transducers

[Headline]Cutting-Edge Absolute Pressure Transducer Revolutionizes Industrial Applications[Subheading]Industry Leader, [Company Name], Redefines Precision Monitoring with State-of-the-Art Absolute Pressure Transducer[Date][City, State] - [Company Name], a renowned innovator in the field of industrial measurement solutions, is set to disrupt the industry once again with their revolutionary Absolute Pressure Transducer. Designed to provide accurate and reliable pressure measurements in various industrial applications, this cutting-edge product is expected to propel the company to new heights.The Absolute Pressure Transducer, developed after meticulous research and development, promises to revolutionize precision monitoring across industries. By eliminating inaccuracies commonly associated with traditional pressure sensors, the company aims to empower businesses to optimize their operations and enhance overall efficiency.Combining advanced technology with industry expertise, [Company Name] has raised the bar by developing a pressure transducer capable of measuring absolute pressure with unrivaled accuracy, precision, and stability. With a wide range of pressure measurement capabilities, this device is capable of handling extreme conditions often encountered in demanding industrial environments.One of the key highlights of the Absolute Pressure Transducer is its ability to account for the impact of environmental factors, such as temperature and humidity, on pressure measurements. Equipped with advanced compensation algorithms, this innovative device ensures accurate readings, eliminating the need for manual adjustments and reducing potential errors.Furthermore, the transducer's robust construction and use of high-quality materials make it suitable for use in a variety of industrial applications. Whether it is monitoring pressure in chemical processes, oil and gas exploration, or water treatment plants, the Absolute Pressure Transducer provides reliable and precise data, helping businesses make informed decisions and maintain optimal system performance.To ensure seamless integration with existing systems, [Company Name] has incorporated various industry-standard communication protocols into the transducer. This allows for easy connectivity with supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and other industrial automation equipment.Addressing the new product release, [Company Name]'s CEO, [CEO Name], expressed his enthusiasm about the Absolute Pressure Transducer and its potential impact on the industry. "We are absolutely thrilled to introduce our state-of-the-art Absolute Pressure Transducer to the market. This product represents our commitment to continually innovate and provide our customers with the most advanced measurement solutions available. We firmly believe that this technological marvel will set new benchmarks in precision monitoring and drive significant improvements in industrial processes."With its strong market presence and extensive customer base, [Company Name] is poised to become a leader in the absolute pressure measurement sector. The company's dedication to research and development, coupled with its commitment to delivering top-notch quality, has positioned it as a trusted partner for industries worldwide.As industries evolve and demand for accurate and reliable pressure measurement systems grows, the Absolute Pressure Transducer from [Company Name] is set to play a vital role in optimizing operations and enhancing overall efficiency. With its cutting-edge features, robust design, and seamless integration capabilities, this device is well-positioned to revolutionize how industries monitor and regulate pressure.About [Company Name]:[Company Name] is a renowned provider of industrial measurement solutions, catering to a wide range of industries globally. With a strong focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for precision measurement requirements. [Company Name]'s comprehensive portfolio of products includes pressure sensors, transducers, temperature sensors, flow meters, and level sensors, among others, providing customers with the tools they need to monitor their critical processes effectively.

Top Water Flow Meter Manufacturers: Quality Products and Reliable Service

Water Flow Meter Manufacturers Introduces Cutting-Edge Technology to Improve Water ManagementIn an effort to enhance water management and conservation efforts, {Water Flow Meter Manufacturers} has introduced a new line of cutting-edge water flow meters designed to provide accurate and reliable measurements of water usage. With a focus on efficient and sustainable water management, these innovative flow meters are set to revolutionize the way water consumption is monitored and controlled.{Water Flow Meter Manufacturers} is a renowned leader in the development and production of high-quality water flow meters. With a strong commitment to innovation and customer satisfaction, the company has continuously pushed the boundaries of technology to deliver state-of-the-art solutions for water management. Their team of experts is dedicated to creating products that not only meet the highest industry standards but also exceed the expectations of their customers.The newly launched line of flow meters is the result of extensive research and development, as well as collaboration with industry experts and stakeholders. These cutting-edge meters are equipped with advanced technology that enables precise measurement of water flow, allowing for real-time monitoring and accurate data collection. This level of accuracy is essential for various applications, including industrial processes, agriculture, commercial facilities, and residential water management systems.One of the key features of the new flow meters is their ability to provide detailed insights into water usage patterns and trends. By capturing and analyzing data on water flow rates, these meters can help identify areas of excessive water consumption, detect leaks or inefficiencies, and ultimately facilitate more informed decision-making for water management. This level of transparency and control is invaluable for businesses and communities striving to optimize their water usage and minimize waste.In addition to their advanced measurement capabilities, the new line of flow meters is designed with user-friendly interfaces and compatibility with digital monitoring systems. This allows for seamless integration into existing water management infrastructure, providing a streamlined solution for monitoring and controlling water flow. With the ability to remotely access and manage data, users can efficiently track water consumption, set usage thresholds, and receive alerts for abnormal flow patterns or potential issues.The introduction of these innovative flow meters aligns with {Water Flow Meter Manufacturers}'s commitment to sustainability and environmental responsibility. By empowering users with the tools to accurately measure and manage water usage, the company aims to support efforts towards efficient water conservation and resource management. This is particularly important in the face of growing concerns about water scarcity and the need to preserve this essential resource for future generations.As part of their dedication to customer satisfaction, {Water Flow Meter Manufacturers} offers comprehensive support and services for their new line of flow meters. Their team of experts is available to provide guidance on system integration, technical assistance, and maintenance to ensure optimal functionality and performance. This commitment to service excellence further underscores the company's reputation as a trusted partner for water management solutions.Moving forward, {Water Flow Meter Manufacturers} is poised to continue driving innovation in the field of water flow measurement and management. With a focus on leveraging technology to address the evolving needs of their customers, the company remains at the forefront of developing solutions that promote efficient water usage and conservation. By combining expertise, quality, and customer-centric values, {Water Flow Meter Manufacturers} is set to make a significant impact on the future of water management.

Top Chinese Manufacturer with 20 Years of Experience in Silicon Pressure Sensors

: Benefits and ApplicationsPressure sensors are essential components in many industrial applications, as they help monitor and regulate pressure in a variety of environments. When it comes to silicon pressure sensors, they are among the most commonly used because of their high accuracy, low power consumption, and compact size. Silicon pressure sensors are designed to detect changes in pressure and provide an electrical output, making them ideal for use in a wide range of industries, including automotive, medical, aerospace, and manufacturing. In this article, we will explore the benefits and applications of silicon pressure sensors.Benefits of Silicon Pressure SensorsAccuracyOne of the primary benefits of silicon pressure sensors is their high accuracy. They can provide precise readings of pressure changes, making them ideal for critical applications such as aerospace and medical industries, where precision and accuracy are paramount.Compact SizeSilicon pressure sensors are also highly compact, making them easy to install in tight spaces. They are typically small enough to fit within electronic devices, which is why they are commonly used in medical devices and other portable equipment.Low Power ConsumptionSilicon pressure sensors require minimal power to function. This makes them ideal for battery-operated devices, such as wireless sensors and portable equipment, where energy conservation is important.DurabilitySilicon pressure sensors are highly durable and can withstand harsh environments. They can function in high temperatures, rugged locations, and corrosive environments without losing their accuracy. This makes them ideal for use in the automotive industry or other areas where sensors are exposed to harsh conditions.Applications of Silicon Pressure SensorsAerospace IndustrySilicon pressure sensors are widely used in the aerospace industry to monitor pressure changes in critical systems, such as fuel injection, hydraulic systems, and pneumatic systems. These sensors play a vital role in ensuring the safety and reliability of aerospace equipment.Automotive IndustrySilicon pressure sensors are used in the automotive industry to monitor fuel pressure, oil pressure, and transmission pressure. These sensors provide essential data to control engine performance, improve fuel economy, and enhance driver safety on the road.Medical IndustrySilicon pressure sensors are widely used in medical devices to monitor vital signs such as blood pressure, heart rate, and respiratory rate. Medical devices such as blood pressure monitors, ventilators, and infusion pumps use silicon pressure sensors to provide accurate and reliable data.Manufacturing IndustrySilicon pressure sensors are used in the manufacturing industry to monitor pressure changes in various processes, including chemical processing and water treatment. These sensors help control the flow of materials in manufacturing processes and maintain optimal conditions for production.ConclusionSilicon pressure sensors are versatile and durable sensors that have a wide range of applications across various industries. They provide high accuracy, low power consumption, and are compact, making them ideal for use in numerous portable devices. As technology continues to evolve, the applications of silicon pressure sensors are expected to grow, making them a critical component of modern industries.

High-Quality Pressure Transmitter With Diaphragm Seal: A Comprehensive Guide

[Company Introduction]{Name of the company} is a leading manufacturer of industrial automation and control solutions. With a focus on innovation and quality, the company has established a strong reputation for providing reliable and high-performance products to a wide range of industries, including oil and gas, petrochemical, pharmaceutical, and more. {Name of the company} is committed to meeting the unique needs of its customers with cutting-edge technologies and exceptional customer service.[Pressure Transmitter With Diaphragm Seal]{Name of the company} is proud to announce the release of its latest product, the Pressure Transmitter with Diaphragm Seal. This new transmitter is designed to accurately measure and transmit pressure readings in challenging industrial environments, where the process medium is corrosive, viscous, or contains solid particles. The diaphragm seal protects the sensitive components of the transmitter, ensuring reliable and accurate measurements even in the harshest conditions.The Pressure Transmitter with Diaphragm Seal is available in a wide range of pressure ratings, from low to high, and is suitable for use with a variety of process media, including liquids, gases, and steam. The transmitter is also available with a range of output options, including analog, digital, and wireless, to meet the diverse needs of different industrial applications.One of the key features of the Pressure Transmitter with Diaphragm Seal is its robust construction, which ensures long-term performance and reliability. The transmitter is made from high-quality materials that are resistant to corrosion and wear, and it is designed to withstand extreme temperatures and pressures. As a result, {Name of the company}'s new transmitter is an ideal solution for industries that require precise and dependable pressure measurement, such as oil and gas production, chemical processing, and power generation.In addition to its exceptional durability, the Pressure Transmitter with Diaphragm Seal is also easy to install and maintain. Its compact and lightweight design makes it suitable for installation in tight spaces, and its intuitive interface allows for quick and simple configuration. Furthermore, the transmitter is equipped with advanced diagnostics and self-calibration features, which help to reduce downtime and maintenance costs, and ensure continuous and accurate measurement.{Name of the company}'s commitment to quality and innovation is evident in the development of the Pressure Transmitter with Diaphragm Seal. The company's team of skilled engineers and technicians have utilized their expertise and experience to design a transmitter that meets the highest industry standards for performance, accuracy, and reliability. Furthermore, {Name of the company} has subjected the transmitter to rigorous testing and validation procedures to ensure its compliance with international regulations and quality assurance guidelines.{Quote from company spokesperson} "We are excited to introduce our new Pressure Transmitter with Diaphragm Seal to the market. This innovative product represents a significant advancement in pressure measurement technology, and we are confident that it will provide our customers with the performance and reliability they need to optimize their processes and operations. At {Name of the company}, we are dedicated to delivering solutions that exceed our customers' expectations, and the Pressure Transmitter with Diaphragm Seal is a clear demonstration of that commitment."{Name of the company}'s new Pressure Transmitter with Diaphragm Seal is now available for purchase, and the company is offering comprehensive technical support and customer service to assist with installation, configuration, and ongoing maintenance. With this new addition to its product portfolio, {Name of the company} has further solidified its position as a trusted provider of advanced industrial automation and control solutions, and is poised to make a positive impact on a wide range of industrial applications.

How to choose the right flowmeter for your needs

Mag Flowmeter, one of the latest technological advancements in the field of flow measurement, is gaining widespread attention in the industrial sector. This innovative device, which utilizes electromagnetic principles to accurately measure the flow of liquids, is revolutionizing the way industries monitor and control their fluid processes. With its precision and reliability, the Mag Flowmeter has become an indispensable tool for industries including water and wastewater management, chemical production, food and beverage processing, and more.The Mag Flowmeter operates on the principle of Faraday's law of electromagnetic induction. By applying a magnetic field to the liquid and measuring the voltage generated as the liquid flows through a pipe, the device is able to provide highly accurate flow readings. Unlike traditional flow measurement methods that rely on moving parts or intrusive sensors, the Mag Flowmeter is non-intrusive and does not obstruct the flow of the liquid, making it ideal for applications where minimal disruption to the process is desired.One of the key advantages of the Mag Flowmeter is its ability to measure a wide range of flow rates with high precision. Whether the liquid is flowing at a slow trickle or at a rapid pace, the device is able to provide accurate measurements, ensuring that industries can monitor their processes with confidence. This versatility makes the Mag Flowmeter suitable for a diverse range of applications, from monitoring the flow of water in municipal systems to measuring the flow of corrosive chemicals in industrial production.In addition to its accuracy and versatility, the Mag Flowmeter is also known for its low maintenance requirements. With no moving parts to wear out or require regular calibration, the device offers long-term reliability and durability. This is particularly advantageous for industries operating in harsh environments or those handling aggressive substances, as the Mag Flowmeter can withstand the challenges posed by such conditions without compromising performance.Furthermore, the Mag Flowmeter is designed for easy installation and integration with existing systems. Its compact and lightweight design allows for convenient placement in tight spaces, and the device can be easily connected to control systems for real-time monitoring and process automation. This seamless integration helps industries improve efficiency and productivity while reducing the need for manual intervention in their operations.The company behind the Mag Flowmeter, [company name], has been at the forefront of flow measurement technology for decades. With a strong focus on research and development, the company has continually pushed the boundaries of what is possible in flow measurement, and the Mag Flowmeter is a testament to their commitment to innovation. By leveraging the latest advancements in electromagnetic technology, [company name] has created a device that is not only highly accurate and reliable but also user-friendly and adaptable to a wide range of applications.In conclusion, the Mag Flowmeter represents a significant advancement in flow measurement technology, offering industries a reliable and precise solution for monitoring and controlling their fluid processes. With its non-intrusive design, wide measurement range, low maintenance requirements, and seamless integration capabilities, the Mag Flowmeter is well-positioned to meet the diverse needs of industries across various sectors. As [company name] continues to refine and expand upon this technology, the future looks bright for the continued evolution of flow measurement solutions.

Highly Accurate Pressure Sensor now available for Precision Applications

[Introduction]In today's highly digitized world, the demand for precise and accurate measurement devices continues to increase across various industries. Pressure sensors, in particular, have become crucial in ensuring the safety, efficiency, and reliability of many processes. Recognizing this need, {company name}, a leading innovator in the field of sensor technology, has recently unveiled its latest breakthrough - the High Precision Pressure Sensor, offering unprecedented accuracy and performance.[Company Introduction]Founded in {year}, {company name} has been at the forefront of sensor technology for over {number of} years. The company's commitment to excellence, innovation, and customer satisfaction has earned them a stellar reputation among industry experts and manufacturers alike. With a dedicated team of engineers and researchers, {company name} continually pushes the boundaries of what is possible in the realm of sensing solutions.[News Content]1. Introduction to the High Precision Pressure SensorThe newly launched High Precision Pressure Sensor by {company name} promises to revolutionize the way pressure is measured across numerous industries. With an accuracy level of up to {accuracy level}, this breakthrough sensor outperforms existing technologies by providing precise measurements in even the most demanding environments. Its cutting-edge design and advanced features make it an ideal solution for applications in industries such as automotive, aerospace, healthcare, and manufacturing.2. Unmatched PerformanceThe High Precision Pressure Sensor boasts an exceptional level of performance due to its state-of-the-art engineering and design. Equipped with advanced signal processing algorithms, this sensor eliminates unwanted noise, interference, and temperature effects, resulting in accurate and reliable measurements. Its robust construction ensures durability and long-term stability, making it suitable for both static and dynamic pressure measurements.3. Versatility and Adaptability{Company name}'s High Precision Pressure Sensor is designed to cater to a wide range of applications. Whether it is monitoring pressure in automotive engines, controlling industrial processes, or ensuring patient safety in medical devices, this sensor offers unparalleled versatility. Its compact size and lightweight construction allow for easy integration into existing systems, making it a seamless addition for manufacturers in various industries.4. Technological AdvancementsThe development of the High Precision Pressure Sensor by {company name} has involved significant technological advancements and meticulous research. The sensor utilizes cutting-edge microelectromechanical systems (MEMS) technology, enabling it to measure pressure with exceptional precision and accuracy. By incorporating digital signal processing techniques, {company name} has eliminated the need for complex external circuitry, resulting in a simplified integration process.5. Industry ApplicationsThe High Precision Pressure Sensor finds applications across a wide array of industries. In the automotive sector, it can be used for tire pressure monitoring systems, engine performance optimization, and brake monitoring. Aerospace industry applications include aircraft cabin pressure management, altitude sensing, and flight control systems. In the healthcare sector, this sensor can monitor blood pressure, infusion pumps, and patient monitoring equipment. Additionally, it finds usage in industrial applications such as hydraulic systems, pneumatic controls, and process monitoring.6. Key Benefits and Market ImpactThe High Precision Pressure Sensor offers several key benefits that make it a game-changer in the market. Firstly, its industry-leading accuracy ensures optimal performance in critical applications, enhancing overall safety and efficiency. Secondly, its compact size and easy integration minimize space requirements, making it an attractive option for manufacturers. Furthermore, the sensor's reliability and long-lasting stability reduce maintenance costs and enhance the lifespan of associated equipment, thereby providing significant cost savings.The launch of the High Precision Pressure Sensor by {company name} marks a significant milestone in the field of pressure sensing technology. Its unrivaled accuracy, exceptional performance, and versatile application possibilities position {company name} as a leader in the sensor industry. As demand for precise measurement devices continues to grow, {company name} remains committed to innovation and delivering cutting-edge solutions that meet the evolving needs of its customers.

Ultrasonic Vs Pressure Water Level Measurement: Which Method is More Reliable?

article about the benefits of ultrasonic water level measurement over pressure-based measurement.Water Level Measurement: Ultrasonic vs. Pressure-basedAccurately measuring water levels is essential in a variety of applications, such as water treatment facilities, irrigation systems, and flood detection systems. Traditionally, water level measurement has been done using pressure-based sensors, which measure the water pressure at a certain depth. However, ultrasonic sensors are becoming increasingly popular due to their many benefits over pressure-based sensors.One major advantage of ultrasonic sensors is their accuracy. Unlike pressure-based sensors, which can be affected by changes in temperature, ultrasonic sensors measure the time it takes for sound waves to travel from the sensor to the water surface and back. This means that ultrasonic sensors can provide highly accurate measurements regardless of environmental fluctuations.Another benefit of ultrasonic sensors is their versatility. Ultrasonic sensors can be used in a wide range of applications, including open channels, tanks, and wells. They can also measure water levels with high accuracy over long distances, making them ideal for large bodies of water or difficult-to-reach areas.Ultrasonic sensors are also more reliable than pressure-based sensors. Pressure-based sensors are more prone to clogging, which can affect their accuracy. On the other hand, ultrasonic sensors usually only require periodic cleaning to maintain their accuracy.In addition, ultrasonic sensors are more cost-effective over the long term. Pressure-based sensors require regular calibration and maintenance, which can be costly. Ultrasonic sensors, on the other hand, have a longer lifespan and require less maintenance, making them a more cost-effective option in the long run.One company that offers ultrasonic water level measurement solutions is {}. With over {} years of experience in the industry, {} provides a range of ultrasonic sensors that are designed for various applications. Their sensors are highly accurate and reliable, making them ideal for a wide range of industries, including water management, agriculture, and environmental monitoring.In conclusion, ultrasonic sensors offer a range of benefits over pressure-based sensors for water level measurement. They offer greater accuracy, versatility, reliability, and cost-effectiveness, making them an increasingly popular choice for a wide range of applications. If you are in need of water level measurement solutions, consider exploring the benefits of ultrasonic technology and contacting {} for more information.

Top Industrial Ultrasonic Level Sensor 2022 - Ultimate Guide + Reviews

Industrial Ultrasonic Level Sensor Revolutionizing Liquid Level MeasurementIn recent years, industries across the world have been benefiting from the innovative application of technology in their processes. One such revolutionary advancement is the Industrial Ultrasonic Level Sensor, a cutting-edge tool that is transforming the way liquid level measurements are conducted in industrial settings. This state-of-the-art sensor, developed by a leading technology company, is set to redefine the standards for accuracy, reliability, and efficiency in liquid level measurement.The industrial sector requires precise and reliable measurements of liquid levels for a variety of processes, including but not limited to chemical processing, water and wastewater treatment, food and beverage production, and oil and gas refining. Traditional methods of measuring liquid levels, such as manual gauging and mechanical float switches, are often prone to inaccuracies, inconsistencies, and inefficiencies. This not only impacts the quality of the processes but also poses safety and regulatory compliance risks.The industrial ultrasonic level sensor, offered by {}, is designed to address these challenges and provide a superior solution for liquid level measurement. Using advanced ultrasonic technology, the sensor emits high-frequency sound waves that travel through the air and are reflected off the surface of the liquid. By measuring the time it takes for the sound waves to return to the sensor, the device can accurately determine the distance to the liquid surface, thus providing an accurate measurement of the liquid level.One of the key advantages of the industrial ultrasonic level sensor is its non-contact measurement capability. Unlike traditional methods that require direct contact with the liquid, this sensor can measure the level of various types of liquids without the need for physical immersion, making it suitable for a wide range of industrial applications. Additionally, the sensor is not affected by factors such as turbulence, foam, or vapor, which can adversely impact the accuracy of traditional measurement techniques.Another important feature of the industrial ultrasonic level sensor is its high level of precision and reliability. The sensor is capable of providing accurate measurements with minimal margin of error, ensuring that industrial processes can be carried out with confidence and precision. This level of accuracy is critical for industries where even minor variations in liquid levels can have significant implications for product quality, process efficiency, and safety.In addition to its accuracy and reliability, the industrial ultrasonic level sensor also offers a high degree of versatility and adaptability. The sensor can be easily integrated into existing industrial systems, and its settings can be adjusted to accommodate a wide range of tank sizes, shapes, and liquid types. This flexibility makes it a valuable tool for industries with diverse and complex liquid level measurement requirements.Moreover, the industrial ultrasonic level sensor is equipped with advanced features that enhance its performance and usability. These include self-cleaning capabilities to prevent buildup of debris or contaminants on the sensor surface, as well as remote monitoring and control capabilities that allow for real-time data collection and analysis. These features enable industrial operators to optimize their liquid level management processes and make informed decisions based on accurate and up-to-date information.As a leading technology company at the forefront of industrial automation and process control, {} has been instrumental in the development and deployment of the industrial ultrasonic level sensor. With a strong focus on research and development, as well as a commitment to meeting the evolving needs of its industrial customers, the company has consistently delivered innovative and reliable solutions for industrial measurement and control challenges.The industrial ultrasonic level sensor is just one example of {}'s dedication to pushing the boundaries of technology and engineering excellence. By combining cutting-edge sensor technology with a deep understanding of industrial processes, the company has successfully positioned itself as a leader in the field of liquid level measurement and automation. With a track record of delivering high-quality products and exceptional customer support, {} has earned the trust and confidence of industrial customers worldwide.As industries continue to evolve and embrace digital transformation, the industrial ultrasonic level sensor stands out as a game-changing innovation that is reshaping the way liquid level measurements are conducted. By providing a powerful combination of precision, reliability, and versatility, this sensor is empowering industrial operators to optimize their processes, enhance their productivity, and ensure the highest standards of quality and safety. With {}'s expertise and commitment to innovation, the future of industrial liquid level measurement is indeed looking brighter than ever.