Sourcing Pressure Transmitter Suppliers: Customized Sensing Products Available

By:Admin

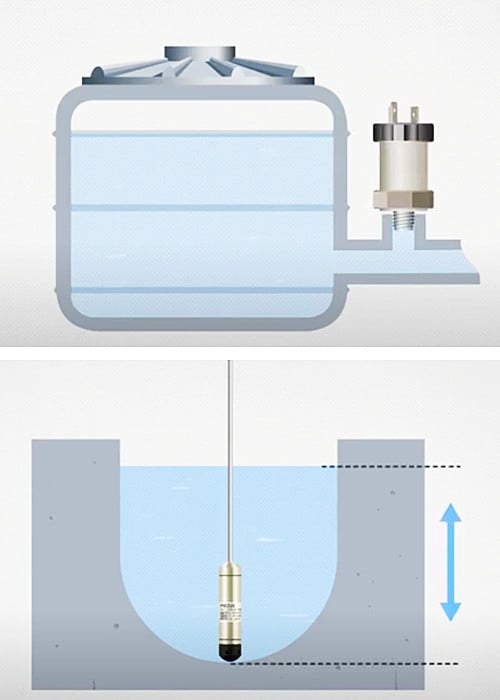

Pressure transmitters are essential in numerous industries, including oil and gas, chemical processing, and water treatment. They measure and transmit pressure readings, which are crucial for maintaining process efficiency and safety. If you're in the market for pressure transmitters, it's essential to choose the right supplier. However, with so many options available, selecting one can be daunting. In this guide, we'll help you choose the best pressure transmitter supplier that meets your needs.

1. Look for Experience

The first thing you should consider is how long the supplier has been in business. Seek a company that has years of experience in designing, manufacturing, and supplying pressure transmitters. Such a supplier will have honed their craft, learned from past mistakes, and developed the necessary expertise to meet your needs. Additionally, an experienced pressure transmitter supplier will keep up with industry trends and standards, allowing them to offer you cutting-edge products.

2. Quality Products

Of course, you want to ensure that the pressure transmitters you're purchasing are of excellent quality. Look for a supplier that uses high-quality materials to manufacture their products and utilizes state-of-the-art technology. The supplier should also have a reputation for producing reliable and accurate pressure transmitters. One way to ascertain the supplier's quality is by checking if they have certification from relevant bodies such as ISO 9001.

3. Customization Capability

The pressure transmitters you purchase should meet your unique needs. A good pressure transmitter supplier should be able to customize their products based on your requirements. They should have skilled engineers who can design and modify pressure transmitters to suit your specific applications. This level of customization ensures that you get the most out of your pressure transmitter, leading to better operational efficiency and accuracy.

4. Technical Support

Technical faults or issues may arise while using pressure transmitters. Therefore, it's crucial to choose a supplier who offers technical assistance and support. The supplier should have a dedicated technical team that you can reach out to for help. Ideally, they should offer on-site support if required and respond quickly to emergency calls.

5. Cost-Effective

When looking for a pressure transmitter supplier, you should consider their pricing. It's essential to strike a balance between quality and cost-effectiveness. Be cautious of suppliers who offer excessively low prices, as this may impact the quality of the pressure transmitters supplied. Look for a supplier who offers value for money, with quality products at a reasonable price.

Conclusion

Choosing the right pressure transmitter supplier is crucial for the success of your operations. By following these guidelines, you can find a supplier that offers quality products, customization capabilities, technical support, and cost-effectiveness. Ultimately, partnering with a reliable pressure transmitter supplier can lead to better performance, improved safety and efficiency, and greater peace of mind. So, be sure to take your time, research your options, and choose wisely.

Company News & Blog

Expert Tips for Efficiently Maintaining Your Effluent Treatment Plant

Effluent Treatment Plant (ETP) is a vital part of any industrial process that deals with waste water. It is responsible for treating the waste water and removing any harmful and toxic pollutants from it before it is discharged into the environment. Failure to maintain ETP can cause pollution and environmental degradation. Therefore, it is crucial to ensure that the ETP is maintained effectively and efficiently.One of the ways to maintain ETP is through regular inspections and prompt repairs. The ETP should be inspected on a routine basis to detect any faults or defects. Any issues identified should be addressed promptly to prevent them from escalating into more significant problems that can cause damage to the system or affect the quality of the effluent. Regular maintenance also helps in avoiding costly repairs and replacements, which can be avoided with timely repairs.Another essential element of ETP maintenance is proper cleaning and maintenance of the treatment units. Cleaning of filter beds, aeration tanks, blower systems and other components of the treatment units is necessary to ensure that the ETP operates efficiently. Poorly maintained ETPs may result in inadequate treatment, which can cause environmental degradation. Proper cleaning helps remove any build-up of debris and pollutants, which helps the ETP to perform efficiently.A crucial aspect of maintaining ETP is training personnel on proper handling and maintenance of the system. It is necessary to provide regular training to the operators of the ETP to ensure that they are adequately equipped to handle any issues that may arise. Providing training not only empowers employees but also reduces the risk of costly failures, lost production time and environmental damage.In addition to regular monitoring and repairs, a well-maintained ETP requires up-to-date records that track treatment efficiency, scheduled maintenance and corrective actions. Records of all activities are essential when demonstrating compliance with regulatory requirements. It helps in monitoring trends in the performance of the plant and identifying areas that require more attention.In conclusion, maintaining an ETP effectively starts with regular inspections, prompt repairs of defects and proper cleaning and maintenance of the treatment units. Routine maintenance of the system not only helps in preventing environmental degradation, but also reduces the cost of repairs and replacements. Proper training of personnel and up-to-date records of the treatment process is also critical in the maintenance of ETP.At NetsolWater, we understand the importance of maintaining an ETP effectively and efficiently. We offer expert services in designing, installing and maintaining ETP systems. Our team of experienced engineers and technicians provide top-notch maintenance services to ensure that our clients' ETP systems operate at peak efficiency. If you need assistance with maintaining your ETP, feel free to reach out to us for professional support.

Find the Right Flow Meters for Your Application at Instrumart" -> "Discover Flow Meters Tailored to Your Needs

IntroductionFlow meters are instrumental devices in the field of fluid measurement and management, used to measure the volumetric flow rate or mass flow rate of a fluid. They are extensively used in a variety of industries such as oil and gas, water treatment, food and beverage, pharmaceuticals, and chemical processing. In this article, we will explore the concept of area flow meters.What are Area Flow Meters?Area flow meters are a type of flow meters that determine the flow rate of a fluid by measuring the cross-sectional area of the fluid in a predefined flow channel. These types of flow meters are also known as variable area flow meters or rotameters.Area flow meters work based on the principle known as the "upward force of flow." This principle states that a fluid flowing in a vertical tube will experience an upward force proportional to the mass flow rate. As the flow rate increases, the cross-sectional area of the tube increases proportionally. Therefore, the position of an indicator within the tube gives an indication of the flow rate.Types of Area Flow MetersThere are several types of area flow meters, each with its own advantages and limitations.Rotameters: As mentioned earlier, rotameters are the most common type of area flow meters. They are typically designed with a vertical glass or plastic tube and a float that moves up and down inside the tube. The position of the float within the tube indicates the flow rate of the fluid.Flow Nozzles: Flow nozzles are used to measure the flow rate of liquids or gases in a pipe. They feature a constriction in the flow path, which causes a pressure drop across the nozzle. By measuring the pressure drop, one can determine the flow rate of the fluid.Venturi Meter: Venturi meters are similar to flow nozzles, but they use a gradual or tapered constriction in the flow path instead. This creates a low-pressure zone, which can then be used to calculate the flow rate.Pitot Tubes: Pitot tubes are used to measure the velocity of a fluid. They feature a probe that is inserted into the fluid stream perpendicular to the flow direction. As the fluid strikes the probe, it is slowed down, creating a pressure difference between the front and the back of the probe. By measuring this pressure difference, the velocity of the fluid can be calculated.Advantages of Area Flow MetersArea flow meters have several advantages over other types of flow meters, such as:Simple Design: Area flow meters generally have a relatively simple design, which makes them less expensive than other types of flow meters.Suitable for Wide Range of Fluids: They are suitable for use with a wide variety of fluids, including liquids and gases.Low Maintenance: They have no moving parts, making them less prone to wear and tear and require less maintenance.Limitations of Area Flow MetersDespite their advantages, area flow meters have some limitations, including:Limited Range: Area flow meters have a limited range of flow rates they can measure, typically between 10:1 and 20:1.Reliance on Accuracy Factors: Area flow meters' accuracy is reliant on the thickness, viscosity and temperature of the fluid being measured.ConclusionArea flow meters are an essential tool used in a wide range of applications to measure fluids' flow rates. They are simple in design, effective and versatile, making them ideal for use in several industries. Whether you are measuring liquids or gases, area flow meters can provide accurate and reliable flow rate measurements, making them an indispensable tool in the world of fluid measurement.

Pressure Transducer Market Predicted to Grow Globally - A Sensor for Measuring Pressure in Gases and Liquids

The Importance of Pressure Transducers in Various IndustriesIn today’s fast-paced world, the importance of accurate measurement tools cannot be emphasised enough. Pressure transducers have emerged as vital components in various industries, from aviation and automotive to oil and gas and healthcare. A pressure transducer is a device used to measure the amount of pressure being exerted within a system or environment. It converts physical pressure into an electrical signal that can be transformed into numerical or visual data for further analysis.Sensotec Pressure Transducer is one such advanced sensor that has revolutionised the measurement industry. It can measure pressure in both gases and liquids, which makes it a popular choice among various industries. This device can detect even minute changes in pressure and provide accurate data that can be used for diagnostics, maintenance and monitoring purposes.One of the significant advantages of pressure transducers is their ability to function in harsh environments. They can withstand extreme temperatures, high pressures, and corrosive conditions, making them ideal for use in industries such as oil and gas, chemical and pharmaceuticals. The robust design of Sensotec Pressure Transducer ensures that it can withstand vibrations, shocks and other external factors that could affect its performance.In the automotive industry, pressure transducers are used to monitor tire pressure and detect leaks and other issues. This information is critical for ensuring vehicle safety, improved fuel efficiency and reduced environmental impact. In aviation, they are used to measure altitude, airspeed, and other parameters that are essential for flight monitoring and navigation.In the healthcare industry, pressure transducers play a vital role in monitoring patient health and critical care. They are used to measure blood pressure, intracranial pressure and other vital signs that can help doctors make prompt and accurate diagnoses.In the manufacturing industry, pressure transducers are used in various applications such as food processing, bottling and packaging. They are used to monitor pressure in pipes and tanks, detect leaks and ensure the smooth functioning of machinery.With the growing demand for accuracy and reliability in different industries, the use of advanced pressure transducers such as Sensotec Pressure Transducer has become increasingly prevalent. Their ability to measure pressure accurately, withstand harsh environments and process data quickly has made them indispensable in numerous applications.In conclusion, pressure transducers have become a crucial part of various industries, from automotive to healthcare and manufacturing. They are used to measure pressure accurately, monitor equipment performance and ensure safety and reliability. With the development of advanced sensors such as Sensotec Pressure Transducer, the measurement industry is set to witness further evolution and growth.

Innovative Pressure Sensor With Displacement Sensor and Elbow Pipe

, Pressure Sensing Technology, Elbow Pipe Sensor, Displacement Sensor, Base, Reflection Members, Deformation, Change of Pressure, Magnitude Measurement.Pressure sensors are critical components of many industrial applications, including measuring fluid and gas pressure in a pipeline. In order to accurately measure pressure, a sensitive and reliable sensor is necessary. That's where the pipe pressure sensor comes into play.At its simplest, a pressure sensor translates pressure changes into electrical signals. The signals are then processed and used for various purposes such as controlling automated equipment, monitoring pressure levels, or providing feedback for safety systems. The pipe pressure sensor is a special type of pressure sensor that is installed directly on an elbow pipe.The pipe pressure sensor comprises three essential components: a displacement sensor, an elbow pipe, and a base. The elbow pipe's first end is fixed on the base, and the displacement sensor is fixed on the base too. The displacement sensor comprises two reflection members; the first is fixed in the main body of the displacement sensor, and the second is movable relative to the main body of the displacement sensor.The second reflection member is connected to the elbow pipe at a first position of the elbow pipe, or alternatively, it is fixed on the base, and the main body of the displacement sensor is connected to the elbow pipe at a first position of the elbow pipe. When the pressure in the elbow pipe changes, the elbow pipe deforms, causing a change in the distance between the first reflection member and the second reflection member. The amount of deformation is measured by the displacement sensor, and the magnitude of the change in pressure is obtained from this measurement.By using an elbow pipe sensor, it's possible to obtain highly accurate measurements of pressure in a pipeline. Elbow pipes are a common feature in many industrial setups. They allow for a change in the direction of flow while reducing turbulence. They are also relatively easy to install and maintain, making them a cost-effective solution.Pressure sensing technology has come a long way in recent years, and the development of displacement sensors has revolutionized the way in which we monitor and control pressure in pipes. The accuracy and sensitivity of these sensors have improved significantly, making them ideal for use in a wide range of applications.Choosing the right pressure sensor for your application is critical. Factors such as pressure range, temperature range, and process compatibility must be considered. Luckily, there is a wide range of options available on the market, making it easier for industries to find the right pressure sensor for their specific needs.In conclusion, the pipe pressure sensor is an essential component in many industrial processes. It enables us to measure pressure accurately and reliably, ensuring that production runs smoothly and safely. From the displacement sensor and elbow pipe to the base and reflection members, each part plays a crucial role in the functioning of this device. As technology continues to advance, we look forward to seeing even more sophisticated pressure sensing solutions in the future.

Smart Differential and Pressure Transmitters for High Performance and Reliability

Azbil Corporation Introduces the AT9000 Advanced Transmitter Model GTX: A High-Performance, Reliable Smart Pressure TransmitterAzbil Corporation, formerly Yamatake Corporation, has recently announced the launch of its new smart differential pressure and pressure transmitter – the AT9000 Advanced Transmitter Model GTX. Designed with microprocessors, the transmitter offers high performance and reliability, and transmits 420 mA DC analog or digital signals in proportion to the measured pressure.The AT9000 Advanced Transmitter Model GTX is an innovative transmitter that offers excellent features, including two-way communication between the transmitter and a CommStaffTM or HART(R) communicator. This allows for operations such as self-diagnosis, range resetting, and zero adjustment, to be easily performed. The smart differential pressure and pressure transmitter is equipped with a range of advanced features that make it ideal for a wide variety of applications.The AT9000 Advanced Transmitter Model GTX is a reliable and accurate transmitter that provides precise pressure readings. Its microprocessor ensures high accuracy and reliability, and it transmits the data in a quick and efficient manner. Its 420 mA DC analog or digital signals are proportional to the measured pressure and provide real-time data that can be used to make important decisions.One of the key features of the AT9000 Advanced Transmitter Model GTX is its versatility. It is suitable for use in a wide range of industrial applications, including the oil and gas industry, chemical processing, water treatment plants, pulp and paper processing, and many more. The transmitter can be used to measure differential pressure, gauge pressure, and absolute pressure, making it a versatile tool that can be used in a range of different applications.Another feature of the AT9000 Advanced Transmitter Model GTX is its user-friendly interface. Its two-way communication capability allows for easy operation and the transmitter can be used with a variety of communication protocols. This means that it can be used with a variety of communication devices, making it highly adaptable and suitable for use in a range of different environments.In addition to its high-performance features, the AT9000 Advanced Transmitter Model GTX is also designed with safety in mind. It is built to be highly durable and is suitable for use in hazardous areas. Its rugged design makes it resistant to harsh environments, and it is designed to withstand extreme temperatures, high humidity, and other challenging conditions.In summary, the AT9000 Advanced Transmitter Model GTX is a high-performance, reliable, and user-friendly smart differential pressure and pressure transmitter that offers a range of advanced features. Its microprocessor-driven technology ensures high accuracy and reliability, and its two-way communication capabilities make it easy to use with a variety of communication devices. It is highly versatile and suitable for use in a wide range of industrial applications, making it an excellent choice for any business looking to invest in a reliable and effective pressure transmitter.

Reliable Tire Pressure Sensor Supplier for car/bus - High-Quality TPMS System Sensors and Kits

Wellgain Auto Technology Co., Ltd.: Your Trustworthy Tire Pressure Sensor Supplier for Cars and BusesWhen it comes to road safety, every component of a vehicle plays a crucial role. Among the crucial components, the tire pressure sensor has become an essential device that every car and bus owner should have. This device lets the driver know the real-time tire pressure, which can prevent accidents that may happen when tire pressure is too low or high. If you're looking for a reliable tire pressure sensor supplier, Wellgain Auto Technology Co., Ltd. should be on top of your list. They're a specialist in producing high-quality TPMS (Tire Pressure Monitoring System) accessories for passenger cars and trucks.Why Choose Wellgain Auto Technology Co., Ltd. as Your Tire Pressure Sensor Supplier?1. Comprehensive product offeringsWellgain Auto Technology Co., Ltd's product line includes TPMS for passenger cars, trucks, and buses. They have a wide selection of Internal and External Transmitter tire pressure sensors that are compatible with various tire sizes. They offer precise readings and help car owners maintain proper tire inflation.2. Excellent manufacturing capabilitiesWellgain Auto Technology Co., Ltd. has a factory with modern production equipment and facilities. They have gained several international certifications, including ISO9001: 2008, CE, RoHS, and FCC, demonstrating that their manufacturing capabilities meet global standards. With their advanced production technology, they can manufacture high-quality tire pressure sensor products in large quantities.3. Dedicated R&D teamWellgain Auto Technology Co., Ltd. has a dedicated R&D team that's responsible for continuously updating their product line to provide better products to customers. They consistently research and develop new tire pressure sensor products that cater to various customer needs. As a result, the company has become a leading tire pressure sensor supplier in China.4. High-quality products and servicesWellgain Auto Technology Co., Ltd. follows strict quality control measures in their production process, starting from raw material sourcing to product delivery. They have a team of experts that ensures each product undergoes thorough inspection before shipping. Additionally, the company provides excellent customer service and support to assist clients with any issues they may encounter.Final thoughtsWhen it comes to reliable and accurate tire pressure sensors, Wellgain Auto Technology Co., Ltd. is a top-tier mechanic solution provider. They're committed to delivering high-quality products and services to their customers, making them an excellent tire pressure sensor supplier. If you're a car owner or run a transportation business, engage this firm for your tire pressure sensor needs. Keywords: Tire Pressure Sensor, TPMS, Wellgain Auto Technology Co., Ltd., Passenger Car, Truck, Bus, Internal Transmitter, External Transmitter, Pressure Sensor Manufacturers, Pressure Transmitter Sensor, TPMS kit sensor, china.

High-Quality Diaphragm Seals for Industrial Applications

article stressing the key advantages of REOTEMP Diaphragm Seals.For many businesses and industries, accurate measurement and monitoring of critical process variables are essential to their operations. The use of pressure instruments such as differential pressure gauges, transmitters, and switches requires diaphragm seals to prevent the process media from damaging the sensitive instrument components. Diaphragm seals also protect the operators and the environment from the dangerous media. For these reasons, selecting the right diaphragm seals is crucial and has a significant impact on the efficiency, safety, and profitability of industrial processes.REOTEMP, a leading manufacturer of temperature and pressure instrumentation, offers a broad selection of diaphragm seals designed and built to exceed industrial standards. With over 50 years of experience in the field, REOTEMP has established itself as a trusted and reliable source of high-quality diaphragm seals for various industries.One of the key advantages of REOTEMP diaphragm seals is their superior product quality and durability. REOTEMP manufactures its diaphragm seals in the USA using strict ISO 9001 quality standards. Each seal is carefully tested for quality, performance, and safety, ensuring that it meets or exceeds industry standards. REOTEMP diaphragm seals are highly resistant to corrosion, wear, and extreme temperatures, making them suitable for harsh and challenging environments.Another significant advantage of REOTEMP diaphragm seals is their versatility and customization options. REOTEMP offers a wide range of materials, configurations, and accessories to meet the diverse needs of various industries. From standard seals to specialized designs for high-pressure applications, REOTEMP can customize diaphragm seals to the specific requirements of its customers. REOTEMP also offers a range of coating options for the diaphragm seals, such as Teflon and Parylene, to further enhance their durability and resistance to challenging media.REOTEMP diaphragm seals are also effortless to install and maintain. They are designed for easy assembly and disassembly, allowing for quick and convenient changes and inspections of the instrument. The seals are also engineered to reduce clogging, blockage, and leakage, improving the overall performance and reliability of the instrument.Aside from the product quality and customization options, REOTEMP also provides excellent customer service and technical support. With its team of highly trained and experienced professionals, REOTEMP can assist its customers in selecting the right diaphragm seals for their applications, providing expert advice and guidance every step of the way.In conclusion, REOTEMP diaphragm seals provide numerous advantages to industrial processes that require precise pressure measurement and monitoring. Their superior product quality, durability, versatility, and customization options make them an ideal choice for various industries, ranging from oil and gas to chemical and pharmaceutical. Furthermore, REOTEMP's commitment to customer service and technical support ensures that its customers receive the best products and services possible.

A Guide to Obtaining Concentration Measurements from Common Inline Sensors

The use of common inline sensors is becoming increasingly popular in the industrial sector, particularly in applications where the control of certain components’ concentration is critical. Investment in expensive analytical equipment can place a significant financial burden on companies, but the use of comparatively affordable inline sensors can yield reliable concentration measurements. By utilizing these sensors correctly, companies can effectively monitor and regulate the concentration of key components in real-time, ensuring they meet desired specifications.Inline sensors are typically placed in the process stream to monitor various parameters, including electrical conductivity, ultrasonic waves, refractive index, and more. However, not all inline sensors are suitable for concentration measurement applications. The sensors must measure a physical parameter that directly correlates with the concentration of the component being monitored. In most cases, the physical parameter is directly proportional to the concentration and can be calibrated to provide concentration measurements.To obtain concentration measurements, the sensor must be calibrated, taking into account various characteristics such as flow rate, temperature, and pressure. Calibration is a critical process that requires precision and knowledge of the measuring system’s characteristics to ensure accurate and repeatable measurements. Companies must validate and verify the calibration process periodically to maintain measurement accuracy and quality.The calibration process involves creating a calibration curve that relates the physical parameter measurement to the concentration of the component being monitored. The calibration curve is then utilized by the sensor to calculate the concentration of the component in real-time. Utilizing appropriate sensors, such as the ones offered by the company {}, helps to ensure that the calibration process achieves the required accuracy and repeatability when determining the concentration of the component being monitored.While inline sensors can be used to accurately assess component concentration levels, there are several challenges that companies may face during their use. Companies must take into account the potential impact of the fluid matrix, which may affect the concentration measurements. In some cases, trace impurities or process fluctuations may also affect the accuracy of the inline measurements, necessitating corrective measures.Regular maintenance and calibration checks are essential in ensuring that inline sensors provide reliable measurements. Regular monitoring of the sensors’ performance can help detect drifts in the system and enable companies to maintain and verify the quality of the measurement results promptly. Monitoring also helps ensure that the sensor continues to operate within specification, and any required corrective actions can be taken promptly.It is important to note that inline sensors provide real-time measurements that can aid in process control. Effective monitoring of component concentrations can help companies avoid costly process disruptions, maintain control of their process, and ensure consistent product quality. The use of inline sensors can also help identify and diagnose issues with the process, before any significant consequences arise.In conclusion, inline sensors provide an efficient means of measuring component concentrations in real-time, enabling companies to take corrective action promptly. By utilizing reliable sensors, such as the ones offered by {}, and implementing an appropriate calibration process, companies can effectively monitor and regulate the concentration of key components, enhancing overall process control and product quality. Ongoing monitoring of measurement quality and system performance is critical in ensuring that the sensor continues to operate within specifications and maintains quality control of the process.

Learn About Efficient Flow Measurement Devices for Accurate Measurements

Flow Measurement Devices Announces Expansion Plans to Meet Global DemandFlow Measurement Devices, a leading manufacturer of flow meters and associated products, have announced their plans for an expansion to their facilities in order to meet the growing global demand for their products.Founded over 30 years ago, the company has carved out a reputation for itself as one of the most innovative and reliable manufacturers of flow measurement equipment. Their products are used in a wide range of industries, from oil and gas to water treatment, and the expansion will allow them to reach even more customers worldwide.The expansion plans will involve the addition of a new manufacturing facility in the US, to complement their existing facilities in the UK and China. This will increase their production capabilities and allow them to better serve customers across the Americas."We are delighted to be announcing our expansion plans at this time," said the company's CEO. "We have seen a significant increase in demand for our products in recent years and this expansion will allow us to continue to meet that demand while maintaining our commitment to quality and reliability."The company's growth has been driven in part by their ongoing commitment to innovation. They have invested heavily in research and development over the years, resulting in products that are not only highly accurate but also easy to use and maintain.Their range of flow meters includes both traditional mechanical designs, such as turbine and positive displacement meters, as well as more advanced devices, such as ultrasonic and electromagnetic flow meters. They also offer a range of associated products, such as flow switches and transmitters.The company's success has not gone unnoticed. They have won a number of awards over the years, including the prestigious Queen's Award for Enterprise in International Trade in 2016. This recognition has helped to raise their profile in the industry and attract new customers from around the world."Our customers trust us to deliver quality products that meet their specific needs," said the CEO. "We take that trust very seriously and are committed to maintaining our high standards as we continue to grow."The expansion is expected to create a number of new jobs in the US, as well as providing a boost to the local economy. The company is also exploring opportunities to partner with local colleges and universities to develop training programs and provide opportunities for students and graduates."We believe in investing in our people and their development," said the CEO. "We want to attract the best talent and ensure that our employees have the skills and knowledge they need to succeed in their roles."Overall, the expansion is a reflection of the company's commitment to providing high-quality products and exceptional customer service. With a global customer base and a reputation for innovation and reliability, Flow Measurement Devices is well-positioned for continued growth and success in the years ahead.

Enhanced Precision and Efficiency: The Future of Digital Water Pressure Sensors Revealed

Digital Water Pressure Sensors Revolutionize Water Management IndustryDigital Water Pressure Sensor (DWPS), a leading provider of innovative and cutting-edge sensor technology, is revolutionizing the water management industry. The company is committed to providing state-of-the-art water pressure sensors to help municipalities and private water companies efficiently manage their water distribution systems. With its advanced technology and comprehensive range of products, DWPS is fast becoming a market leader in the field.DWPS is dedicated to providing an unparalleled level of product quality and service to its customers. The company has invested heavily in its research and development programs, which has allowed it to design and manufacture highly accurate and reliable sensors suitable for even the most demanding applications. Its state-of-the-art facility and highly trained staff ensure that every sensor produced by DWPS is of the highest quality and meets the industry's rigorous quality standards.With its sensors' help, DWPS is helping municipalities and water companies reduce water waste and optimize their operations. Its sensors can monitor water pressure and flow rates, detect leaks, and alert operators in real-time of any abnormal conditions. By having access to this data, water management operators can make informed decisions on water infrastructure maintenance and upgrades. The result is a more efficient and cost-effective water distribution system that benefits both the operators and the end-users.One of the key features of DWPS's sensor technology is its ability to communicate autonomously. Its sensors can be equipped with wireless connectivity that allows them to communicate with a central hub or other sensors. This means that operators can access data from multiple sensors simultaneously and in real-time, providing them with a comprehensive view of the entire water distribution system. Through the incorporation of big data analytics and machine learning, DWPS's sensors can also provide predictive maintenance, alerting operators of potential problems before they occur, allowing them to undertake maintenance without disrupting the water supply.DWPS's sensors have also been designed with flexibility in mind. They can be installed in a range of applications, including water storage tanks, pipelines, and pumping stations. They are highly adaptable and can be customized to meet specific customer requirements, in terms of size, range, and accuracy. DWPS offers a range of sensors suitable for various applications, including high-pressure applications, extreme temperature environments, and corrosive environments.DWPS's sensors are also designed to be easy to install and operate. They come with user manuals, instructional videos, and technical support to ensure that customers have all the information they need to install and operate the sensors effectively. With its online portal, customers can access real-time sensor data, download reports, and receive alerts via email or text message. This means that operators can monitor their water distribution systems from anywhere, at any time.DWPS's innovative sensor technology is changing the water management industry, providing municipalities and private water companies with the tools they need to optimize their operations and reduce water waste. With its commitment to research and development, product quality, and customer service, DWPS is poised to become a leading provider of sensor technology in the coming years.